DTG (Direct to Garment) printing is becoming the most preferred printing technology in the POD industry thanks to its ability to reproduce images with exceptional sharpness, smooth color transitions, and high realism. As U.S. customers increasingly demand better print quality, understanding why DTG stands out and how to optimize your designs for this technology is the key for POD sellers to increase conversion rates, reduce refunds, and build a long-term, trustworthy brand.

What Is DTG Technology?

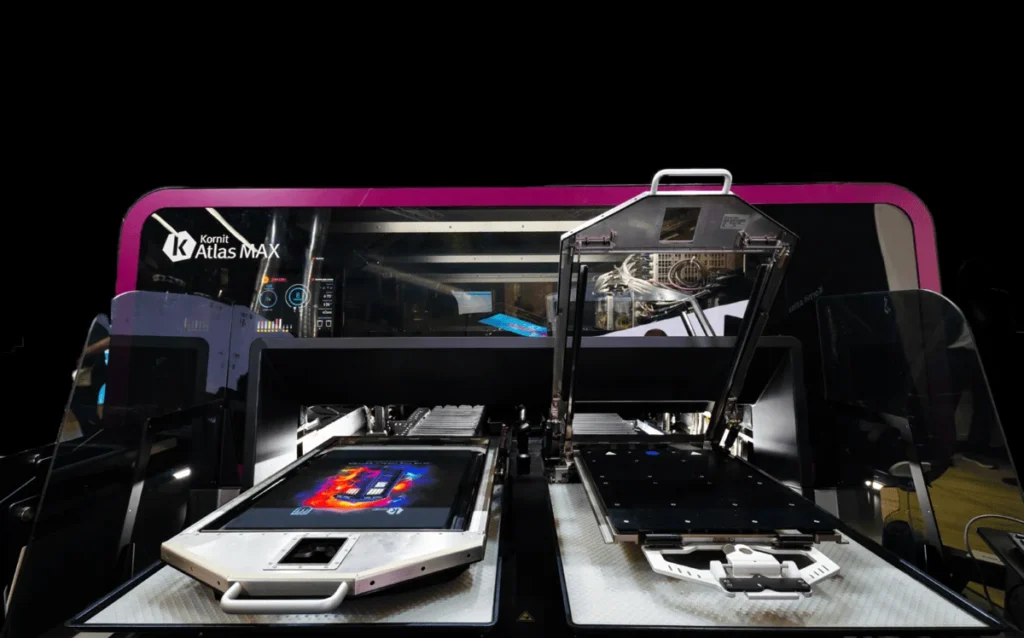

DTG (Direct to Garment) is a printing method that uses specialized digital inkjet technology to spray ink directly onto the fabric surface.

Imagine the color printer in your office except instead of printing on paper, it prints on a T-shirt, and instead of standard office ink, it uses eco-friendly, water-based ink formulated specifically to bond with cotton fibers.

The basic DTG workflow includes:

- Fabric Pre-Treatment: The shirt is sprayed with a special solution that helps the fibers absorb ink better, prevents bleeding, and enhances color vibrancy.

- Digital Printing: The printhead moves back and forth, spraying ultra-fine micro-droplets of ink using the CMYK color system (plus white ink for dark garments) to recreate the artwork.

- Heat Curing: The printed shirt is placed in a heat press or industrial dryer to cure the ink, ensuring it bonds firmly with the fabric and achieves long-lasting wash durability.

Unlike screen printing (which requires making screens) or DTF (which prints onto a film before transfer), DTG prints directly onto the garment. This “direct” characteristic is the key to the superior sharpness and detail we will explore below.

6 Reasons Why DTG Prints Are Sharper Than Other Technologies

In the race for print quality within the POD market, Direct-to-Garment (DTG) consistently holds the top position for realism and sharpness. DTG is far more than simply “printing on a shirt” it is a precise combination of chemistry, mechanical engineering, and advanced image-processing software. Below are the six technical factors that allow DTG to outperform other printing methods in terms of clarity and detail.

Exceptional Ability to Reproduce Fine Details

DTG’s greatest strength lies in its ultra-precise digital printheads, capable of reaching up to 1200 dpi. Unlike screen printing (limited by mesh density) or vinyl/decal printing (which struggles with very small cuts), DTG can perfectly render:

- Ultra-thin outlines: Strokes as small as 1–2 pixels remain clean and continuous without breaking.

- Small typography: Tiny quotes, signatures, or taglines under logos still appear sharp and easy to read.

- Complex textures: Challenging effects such as realistic fur, glow lighting, smoke, and mist are vividly reproduced thanks to DTG’s precise micro-ink control.

- Layered compositions: For multi-layer Fantasy or Anime designs, DTG separates layers clearly, creating visual depth that heat-transfer methods cannot achieve.

Wide Color Range – Smooth Gradients with No Banding

One major frustration for sellers using DTF or screen printing is “banding” – visible striping in gradient areas. DTG eliminates this problem completely. Thanks to its direct color-blending technology, DTG produces ultra-smooth gradients with no harsh transitions between tones. This is especially important for top-selling niches such as pet portraits, family illustrations, and scenic artwork, where maintaining depth and 3D realism is essential.

Ultra-Fine Ink Spraying Technology

Modern DTG printers use micro-spray technology, ejecting millions of picoliter-sized ink droplets in a randomized dot matrix.

- No jagged edges: The edges of the printed artwork appear smooth, completely eliminating the stair-step pixelation seen in older digital printing methods.

- High resolution: The dense pixel structure ensures the print looks naturally sharp both from afar and up close, without graininess or ink bleeding.

Excellent for Full-Front and Large Artwork Printing

With film-based technologies (such as DTF or decals), printing a large design (e.g., 12×16 inches) often creates a thick, uncomfortable “armor plate” on the wearer’s chest. In contrast, DTG allows sellers to freely create full-front designs, wide backgrounds, or large, detailed artworks while still maintaining breathability.

Even with oversized prints, DTG ensures consistent sharpness across both the edges and the center of the artwork, without blurring, fading, or losing detail at the corners.

How Does DTG Compare to DTF in Terms of Sharpness?

DTF (Direct to Film) has recently become a strong competitor due to its lower cost. However, when it comes to sharpness and visual aesthetics, DTG and DTF serve very different purposes.

| Criteria | DTG (Direct to Garment) | DTF (Direct to Film) |

| Image Foundation | The image is reproduced by dyeing the fabric fibers. | The image is a plastic (PET) film layer transferred onto the fabric. |

| Detail Reproduction | Extremely high. Excellent for fine details < 1mm, smoke effects, fog, and vintage textures. | High, but very small details or thin lines may be lost during film peeling or may not adhere properly. |

| Gradient Performance | Smooth. Transitions from dark to light blend seamlessly into the shirt color. | Decent. However, gradients that fade to transparency often show visible halftone dots, making the transition less smooth. |

| Visual Aesthetic | Looks “real” and premium similar to high-end boutique apparel. | Looks glossy or plastic-like. Colors are vibrant but often feel artificial (sticker-like). |

| Edge Sharpness | Soft but precise edges that blend naturally into the fabric texture. | Very crisp edges sometimes too sharp, creating a stiff visual appearance. |

Which Types of Designs Should Sellers Choose to Maximize DTG Quality?

Owning modern printing technology is only the necessary condition. To achieve a flawless final product, the quality of the input design file is the sufficient condition. In the POD industry, there is one unchanging rule: “Garbage in, garbage out.” If the source file is poor, the printed result will never look good.

Below is a checklist of six golden factors every seller must master to optimize design files for DTG printing:

Use High-Resolution Design Files – The “300 DPI Rule”

Resolution is the critical factor that determines print sharpness.

- The golden standard: Always design and export your artwork at 300 DPI (Dots Per Inch) at the actual print size (e.g., 12×16 inches).

- Absolutely avoid: Downloading low-quality images (72 DPI) from the internet and upscaling them. This only increases the fake file size without adding real detail, resulting in prints that look pixelated and blurry.

- Pro tip: Work with the correct artboard size from the beginning. The sharper the original file, the more data the DTG printer has to accurately reproduce the artwork.

Avoid Extremely Thin Strokes

Although DTG is well-known for handling fine detail, ink and fabric fibers still have physical limitations.

- The risk: Strokes thinner than 1 pixel may not provide enough surface area for ink adhesion, causing them to disappear or appear faint after pre-treatment.

- The solution: Ensure that all linework and small text have a minimum thickness of 1.5px–2px. This not only improves print clarity but also enhances long-term durability after multiple washes.

Prioritize PNG with Transparent Background or High-Quality TIFF

The file format directly affects how the printer processes the background.

- PNG (Portable Network Graphics): This is the most commonly used format in POD. Always use PNG 24-bit or 32-bit to preserve a transparent background. This is crucial for achieving smooth smoke, fog, glow, or shadow effects that blend naturally into the shirt color.

- TIFF: If your design file is large and you need to preserve every bit of color data, TIFF is a professional, high-fidelity option.

Increase Color Contrast

Computer screens emit light (RGB), while T-shirts absorb light (CMYK). This means printed designs often appear slightly darker or more muted than what you see on screen.

- Technique: Before exporting your file, “compensate” by increasing Saturation and Contrast by about 10–15%.

- Effect: This is especially useful for printing on dark garments (black, navy). It helps the print “pop,” appear more vibrant, and prevents the artwork from blending into the fabric background.

Choose the Right Garment Blank – The “Foundation” Factor

DTG works based on ink absorption into fabric fibers. Therefore, the fabric material determines 50% of the final print quality.

- Top Priority: 100% Cotton Natural cotton fibers absorb water-based DTG ink best, producing the most accurate and vibrant colors.

- Ring-Spun Cotton: A premium type of cotton with a smoother, softer surface and minimal lint. The flatter the fabric surface, the sharper the print.

- FlashShip Recommendations: To optimize both profit margin and print quality, sellers should consider:

- Bella+Canvas 3001: Extremely smooth surface; exceptional DTG results.

- Gildan 64000 (Softstyle): A budget-friendly option that still delivers good DTG quality.

- Comfort Colors 1717: Thick, vintage-style garment, currently a hot trend, with excellent DTG ink absorption.

Avoid “Overcrowded” Designs – Make Use of Negative Space

Do not try to cram too many elements into a small print area.

- The problem: A large, fully ink-covered (solid block) design can feel thick, heavy, and suffocating when worn creating an “armor plate” effect.

- The solution: Make intentional use of negative space the unprinted areas that reveal the garment’s natural fabric color. This not only makes the design look cleaner, more artistic, and visually breathable, but also keeps the shirt softer, reduces ink usage, and lowers printing costs (if the print provider charges based on ink volume).

In an increasingly competitive POD market where U.S. customers place strong emphasis on product experience choosing a high-quality printing technology like DTG is no longer an “optional upgrade”; it has become a mandatory standard. DTG delivers sharp prints, smooth details, high realism, and excellent color retention all of which directly impact 5-star review rates, refund rates, and seller profit margins.

If you want to optimize your cotton product lineup, elevate your print quality to brand standards, or need design guidance tailored for DTG, the FlashShip team is always ready to support you. Contact our hotline at (+84) 943 024 337 for detailed consultation.