In the booming landscape of e-commerce and Print on Demand (POD) in the United States, choosing the right Fulfillment location doesn’t just impact delivery speed—it directly determines operational costs and customer experience. California and Texas have emerged as the two major “hotspots” for Fulfillment in the U.S., but which one is truly the optimal choice for POD sellers in 2025?

This article will help you understand the key differences between Fulfillment in Texas and California, analyze Texas’s strategic advantages, and explain why more and more sellers are shifting their operations to Texas to optimize speed, reduce costs, and maximize profits with FlashShip.

Overview of the U.S. E-Commerce Fulfillment Market

The U.S. e-commerce market is a multi-trillion-dollar battlefield. Online retail revenue is projected to surpass $1.7 trillion by 2027. This explosive growth especially following the pandemic has placed immense pressure on the nation’s logistics and fulfillment infrastructure.

The Era of “Amazon Prime Expectations”

Amazon has changed the game forever. Today’s customers consider free two-day shipping a standard, not a luxury. For POD sellers, if it takes three days to print a shirt and another five to seven days for shipping, they’ve practically lost the race before it even begins. This new reality forces Third-Party Logistics (3PL) providers and POD fulfillment partners to completely rethink their operational strategies.

The Role of 3PL and POD Fulfillment Partners

For POD sellers, running their own warehouse managing staff, printing, packaging, and shipping—is virtually impossible. They rely 100% on fulfillment partners. These partners don’t just store product blanks (T-shirts, mugs, hats, etc.); they also act as production facilities, quality control stations, and shipping hubs.

Therefore, the location of a fulfillment partner directly impacts four core factors for sellers:

- Shipping Speed: The #1 factor influencing conversion rates and customer satisfaction.

- Fulfillment Cost: Including storage, pick-pack, and printing fees.

- Shipping Cost: Determined by the distance between the warehouse and the customer.

- Reliability: The ability to process orders smoothly, even during Q4 peak season.

The U.S. fulfillment market is witnessing a clear geographical shift. Companies are moving away from expensive coastal hubs and relocating into the heartland to optimize all four of these factors. And no rivalry illustrates this shift more clearly than the showdown between California and Texas.

Overview of the Two Largest Fulfillment Regions in the U.S.

Traditionally, the West Coast, dominated by California, and the East Coast, with major hubs in New Jersey and New York, have served as the two primary pillars of U.S. logistics. However, the rise of the Central region, led by Texas, is rapidly reshaping the nation’s fulfillment map.

California: The Traditional Western Gateway

- Location: West Coast, United States.

- Major Hubs: Los Angeles (particularly the Inland Empire area) and the San Francisco Bay Area.

- Historical Strengths: The Los Angeles/Long Beach Port complex is the largest import gateway from Asia. Billions of dollars in goods including apparel blanks enter the U.S. through these ports. The long-standing logic has been: “Where the goods land, fulfillment follows.”

- Scale: California’s internal consumer market is the largest in the country. In theory, locating warehouses here allows immediate access to over 40 million residents.

- Infrastructure: Extensive highway systems (I-5, I-10) and the Los Angeles International Airport (LAX) provide strong connectivity for domestic and international transport.

Texas: The New Logistics Heart of America

- Location: South-Central United States.

- Major Hubs: Dallas/Fort Worth (DFW), Houston, and rapidly growing cities such as Austin and San Antonio.

- Strategic Advantages: Texas occupies a truly central location. It borders Mexico a key trade partner and is home to the Port of Houston, one of the busiest ports in the U.S. and a vital gateway to the Gulf of Mexico.

- Scale: Texas has the second-largest economy in the U.S. (after California) and is expanding at an extraordinary pace. It also boasts the fastest population growth in the nation.

- Infrastructure: The DFW International Airport ranks among the world’s busiest, serving as a mega-hub for American Airlines, UPS, and FedEx. Texas’s vast network of railways and interstate highways (I-35, I-20, I-10) radiates in all directions, enabling efficient nationwide distribution.

Detailed Analysis: Fulfillment in California vs. Texas

This comparison isn’t just about geography it’s about costs, regulations, and risk management. For POD sellers, every dollar saved in operational expenses directly translates into higher profit margins.

Key Comparison Factors

| Factor | Fulfillment in California (Main Hub: Inland Empire, Los Angeles) | Fulfillment in Texas (Main Hub: Dallas/Fort Worth – DFW) | Impact on POD Sellers |

| 1. Warehouse Costs | Extremely high. Industrial warehouse rental rates are among the most expensive in the world. | Reasonable. Rent can be 40–60% lower than in California. | High warehouse costs = higher fulfillment fees (pick-pack, storage), which directly reduce profit per product. |

| 2. Labor Costs | Very high. The state’s minimum wage is $16/hour in 2024, and even higher in certain cities. | Competitive. No state-mandated minimum wage (federal rate of $7.25/hour applies), though actual wages average $15–$18, still lower than California due to a lower cost of living. | High labor costs = higher handling (printing, packaging) fees. |

| 3. Legal Environment | Complex. Known for strict labor regulations (break laws, overtime rules, AB5) and stringent environmental standards. | Business-friendly. Known for its pro-business climate, fewer regulatory barriers, and no state corporate income tax. | Fulfillment partners in California face higher compliance and legal costs, which are inevitably passed on to sellers. |

| 4. Taxation | High. Both corporate and sales taxes are among the highest in the U.S. | Low. No state-level personal or corporate income tax. | A favorable tax environment allows 3PL and POD providers in Texas to operate with leaner cost structures. |

| 5. Disruption Risk | High. Port congestion at Los Angeles/Long Beach is a chronic issue. There’s also a high risk of port worker strikes, wildfires, and earthquakes. | Low. Port of Houston operates efficiently. Main risks include hurricanes (Gulf region) and tornadoes, but these rarely cause system-wide disruption like in California. | Port congestion in California can delay apparel blanks for weeks, causing out-of-stock issues during peak seasons. |

| 6. Geographic Position | Off-center (West Coast). | Central. | This is the key factor analyzed in greater detail below. |

Why Fulfill in Texas?

From the comparison above, it’s clear that Texas holds strong advantages in both cost-efficiency and operational stability. However, the decisive edge the true game-changer lies in Texas’s strategic geographic location and superior transportation infrastructure.

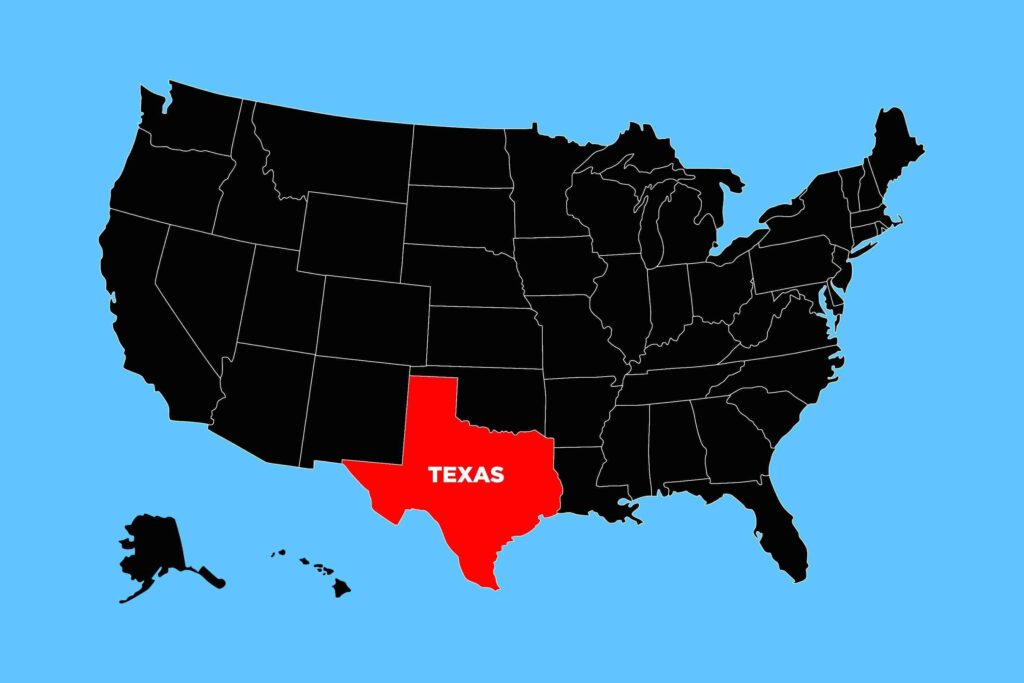

Texas’s Strategic Geographic Advantage: “The Center of America”

Imagine the United States as a shipping map divided into zones. The farther the destination from the warehouse, the higher the shipping zone and with it, both cost and delivery time.

The California Scenario: If you fulfill from Los Angeles (Zone 8), shipping an order to New York, Boston, or Miami (also Zone 8) typically takes 4–5 business days via Ground Shipping. In today’s fast-paced e-commerce environment, that’s simply too long. In essence, you’re losing access to nearly 50% of the U.S. population concentrated on the East Coast.

The Texas Scenario: If you fulfill from Dallas, your warehouse is positioned almost perfectly in the middle of the country (Zone 4/5).

- Shipping to the East Coast (New York, Florida): 2–3 days

- Shipping to the West Coast (Los Angeles, Seattle): 2–3 days

- Shipping to the Midwest (Chicago, Ohio): 1–2 days

In other words, a warehouse in Texas can reach over 93% of the U.S. population within just 3 days of ground shipping.

Why This Is the “Ultimate Weapon” for POD Sellers

- Higher Conversion Rates: Showing “Delivery in 3–4 Days” on your product page dramatically increases conversions compared to “7–10 Days.”

- Reduced WISMO Complaints: Fewer “Where Is My Order?” inquiries save customer service time and costs.

- More Positive Reviews: Fast delivery leads to more 5-star customer feedback.

- Lower Shipping Costs: Instead of paying high cross-country shipping fees (CA → NY), you only pay regional rates (TX → NY), effectively reducing your average shipping cost.

- Bottom line: Texas isn’t just a cheaper option it’s a strategic powerhouse that helps POD sellers deliver faster, lower costs, and scale smarter across the U.S.

Infrastructure & Superior Delivery Speed

Texas’s geographic advantage would mean little without the infrastructure to support it. Fortunately, the state has invested billions of dollars to become a logistics superhub.

A Massive Air Cargo Hub

The Dallas/Fort Worth International Airport (DFW) is not just a passenger airport it’s one of the largest air freight hubs in the world. Both FedEx and UPS operate major distribution centers here, and Amazon Air also maintains a large regional hub.

Impact on POD: For expedited orders, being near an air freight superhub like DFW means your packages can be printed, packed, and flown to anywhere in the U.S. within just a few hours after production.

The “Superhighways” of America

Texas sits at the crossroads of the country’s most critical transportation arteries:

- I-35: The “NAFTA Superhighway,” running from Mexico through Texas all the way north to Canada.

- I-10: The main East–West corridor connecting California (West Coast) to Florida (East Coast), passing straight through Texas.

- I-20: Another major East–West route linking Texas with the Southeastern states.

This extensive network allows USPS, UPS, and FedEx trucks to depart from Dallas and move efficiently to every corner of the nation with minimal transit time.

An Efficient Alternative Seaport (Port of Houston)

For POD sellers importing bulk apparel blanks from overseas (e.g., Vietnam, China), the Port of Houston offers an excellent alternative to California’s congested ports. It is one of America’s top container ports less crowded, highly automated, and directly connected by rail to Dallas, ensuring that shipments are processed and released quickly.

In short, Texas combines world-class logistics infrastructure, multimodal connectivity, and central positioning, giving sellers a unique edge in both speed and scalability.

Optimized Operating Costs, Higher Profit Margins

As outlined in the comparison table, everything in Texas is more cost-effective:

- Lower warehouse costs: Your fulfillment partner (like FlashShip) operates with lower fixed expenses.

- Lower labor costs: Reduced handling costs (printing, packing) per order.

- Lower compliance costs: Fewer legal risks and unexpected expenses.

What does all of this mean? It means your base cost (product cost) can be significantly optimized. When your base cost decreases even by just $0.50 or $1.00 per shirt your profit per order increases dramatically. This improvement also gives you more flexibility to run ads, offer discounts, or provide free shipping, helping your store stay competitive and grow sustainably.

The “Critical Weaknesses” of Fulfillment in California

In contrast, choosing to fulfill orders in California is increasingly revealing several critical weaknesses for a business model as time- and cost-sensitive as Print on Demand (POD).

Sky-High Costs That Erode Profit Margins

This is the most obvious drawback. Warehouse rental rates in the Inland Empire Southern California’s main logistics hub have skyrocketed in recent years, and labor costs have followed suit.

Fulfillment partners have no choice but to pass those costs on to you, the seller. If you sell a T-shirt for $25 and your base cost increases by $1.50 simply because your warehouse is located in California, you’ve already lost a significant portion of your profit margin.

Off-Center Location Slows Nationwide Delivery

As previously analyzed, the West Coast location is a major disadvantage for nationwide shipping. You can’t build a reliable, U.S.-wide POD brand if half your customers on the East Coast have to wait 7–10 days to receive their orders. They’ll simply buy from a competitor with a centrally located warehouse.

Chronic Port Congestion

The POD industry heavily depends on a stable supply of product blanks. Port congestion events at Los Angeles/Long Beach occur almost every year due to strikes, truck shortages, or vessel backlogs, and they can cripple your supply chain.

Imagine it’s November (Q4 season) and your T-shirt blanks are stuck offshore for three weeks, that’s a revenue disaster waiting to happen.

The “Maze” of Labor Regulations Creates Instability

California’s complex legal environment breeds uncertainty. A single new labor law such as AB5, which impacted truck drivers can be passed and immediately increase transportation costs or trigger strikes. This kind of instability is the enemy of logistics, an industry that relies on consistency and predictability to operate efficiently.

Choosing the Right Fulfillment Location Is a Strategic Decision

Understanding and selecting the right Fulfillment location is not merely a question of warehouse placement it’s a core strategic choice that determines speed, cost efficiency, and customer experience in the Print on Demand model.

When sellers fully grasp the differences between California and Texas, and leverage Texas’s geographic advantages, logistics infrastructure, and flexible operating environment, they are building a solid foundation for their POD business one where every order is produced quickly, delivered on time, and generates sustainable profit.

Most importantly, partnering with a trusted Fulfillment provider like FlashShip allows you to focus on what truly matters: design, branding, and business growth.

For inquiries, please contact FlashShip at (+84) 943 024 337 or visit https://flashship.net to receive personalized consultation and start your Made-in-USA Fulfillment journey today.